In a significant stride toward achieving a seamless integration of recycling processes within the realm of automotive Hybrid Batteries, Toyota has embarked on a collaboration with Redwood Materials to augment their existing agreement. This partnership is poised to revolutionize the recycling of lithium batteries, marking a pivotal moment in sustainable practices within the automotive industry.

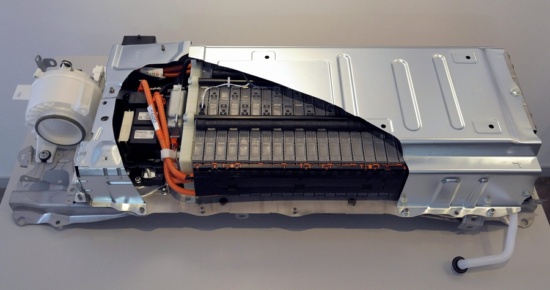

The objective of this novel collaborative endeavor is to pioneer innovative approaches for managing end-of-life car batteries from Toyota’s electric and hybrid models. Picture this: the Hybrid Batteries from aging Prius vehicles, for instance, could find new life, or their components might be repurposed to craft batteries for cutting-edge Toyota vehicles. As the collaboration deepens, Toyota is set to procure copper foils—integral components forming the positive and negative electrodes—from Redwood Materials. This strategic move positions Toyota to commence in-house battery production in the foreseeable future.

Anticipating a surge in the demand for Hybrid Batteries recycling, Toyota is gearing up to address the increasing number of electric and hybrid cars approaching the end of their operational lifespan. Notably, the initial Prius models, introduced over two decades ago, are among those reaching this critical juncture. Given that a substantial proportion of these aging Prius vehicles were originally sold in California, they are poised to converge on Redwood’s facilities in Nevada. Industry analysts predict that the collaboration will yield the production of approximately 5 million batteries in the coming years.

This collaborative initiative aligns seamlessly with Toyota’s broader commitment to sustainability. The Japanese automotive giant has set ambitious targets, aiming for carbon neutrality across its factories by 2035 and extending this commitment to its vehicles by 2050. Crucial to this vision, particularly in North America, is the incorporation of recycled materials in the production of new batteries at the Toyota Battery Factory, scheduled to commence operations in 2025.

Concurrently, Redwood Materials is actively pursuing the expansion of its Nevada facility and the establishment of a new facility in South Carolina. The company’s mission is centered around recycling and extracting materials crucial to battery manufacturing. In adherence to the agreement with Toyota, Redwood will supply a minimum of 20% lithium and nickel, along with 50% cathode cobalt, derived from recycled Hybrid Batteries.

In essence, the collaboration between Toyota and Redwood Materials emerges as a key catalyst in advancing sustainable practices within the automotive industry. This partnership not only breathes new life into aging batteries but also sets the stage for a future where recycling is at the forefront of technological innovation and environmental stewardship.